The Power of Automated Sampling and Real-Time Moisture Analysis

It’s widely understood that moisture content of woody biomass critically influences energy output. The higher the moisture content, the less energy it generates during combustion. For this reason, biomass power facilities rigorously measure the moisture content of incoming biomass to ensure they receive the fuel quality they’re paying for. This measurement is even formalized in industry standards such as ASTM and ISO.

What’s less recognized, however, is that even the most precise moisture sensors can fail if the samples themselves aren’t representative of the biomass load. When manual samples are taken from only the surface or a couple of locations on the load, they often yield drier readings than the actual moisture level throughout the load. This practice can result in a significant underestimation of the total moisture content, with facilities unknowingly paying more for biomass that contains less usable energy than anticipated.

There Must be a Better Way

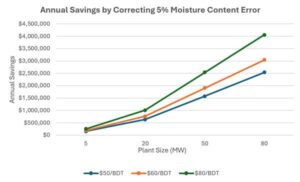

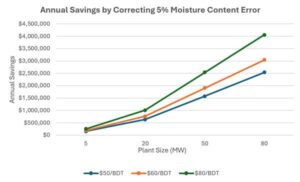

With the introduction of automated sampling systems that take multiple samples from various depths, facilities can now achieve a truly representative measurement of moisture content. These systems correct for the bias introduced by manual sampling, ensuring more accurate moisture content data points. The impact on procurement costs is substantial: an average-sized biomass power facility could potentially see savings exceeding $1 million annually by correcting this sampling error.

Automating moisture measurement as part of the sampling process brings additional benefits, providing instant moisture data and allowing real-time adjustments.

Savings Calculations for a Biomass Plant

In Figure 1, considered is a 20-MW, electricity-only biomass power plant located in the Northwest U.S. To sustain continuous operations, the plant requires approximately 480 megawatt-hours (MWh) of fuel energy per day. At a plant efficiency of 25%, the required fuel energy input is 1,920 MWh per day, which translates to 770 metric tons (mt) of biomass, assuming an average energy content of 2.5 MWh per ton, when moisture content is 50%. This is equivalent to 25 truckloads of 30 mt each.

- Expected Cost with 45% Moisture (Manual Sampling):

- Expected Dry Weight:

770 MT × (1 − 0.45) = 423.5 MT (BDT)

- Procurement Cost:

5 MT × $60 = $25,410

- True Cost with 50% Moisture (Automated Sampling):

- Actual Dry Weight:

770 MT × (1 − 0.50) = 385 MT (BDT)

- Procurement Cost:

385 MT × $60 = $23,100

- Results:

- Daily Savings from Corrected Sampling:

$25,410-$23,100= $2,310

- Annual Savings (assuming 330 operational days):

$2,310 × 330 = $762,300

We assume a $60 per bone-dry ton (BDT) biomass price and a 5% moisture measurement error in manual sampling, which is a typical error based on Prometec’s field data from biomass facilities worldwide.

This example shows that a 5% moisture measurement error from unrepresentative manual sampling can lead to overpayments exceeding $760,000 million annually for a 20-MW biomass electricity plant. Automated sampling systems eliminate these inaccuracies, ensuring precise moisture readings and significant cost savings.

Bone Dry vs. Green Tonnage

For facilities paying for wood chip fuel based on green tonnage, improving sampling and moisture measurement accuracy may not directly affect pricing. However, automated sampling with real-time moisture data provides several other benefits.

• Optimized fuel blending: Knowing moisture content before unloading allows facilities to blend fuel more effectively across different yard piles for optimal drying.

• Boiler efficiency adjustment: For facilities that burn biomass directly upon arrival, accurate moisture readings enable real-time boiler adjustments, enhancing combustion efficiency.

• Employee safety: Automated systems eliminate the need for employees to climb ladders to collect samples, reducing fall risks and exposure to biomass dust.

• Continuous 24/7 receiving: With automation, truck drivers initiate sampling and measurement without needing facility staff present, allowing receiving operations to run around the clock.

• Accurate feedback to suppliers: If a biomass load exceeds the agreed moisture range, plant managers can notify suppliers immediately, or even give them access to real-time data online. This continuous monitoring encourages suppliers to consistently deliver higher-quality biomass, as they aim to avoid penalties or complaints. As a result, power facilities benefit from lower average moisture content in their fuel, reducing the total biomass needed and saving procurement costs over time.

Prometec Q-Robot: A Pioneering Solution in Automated Sampling

For over a decade, Prometec has been at the forefront of developing fully automated biomass sampling solutions, now in use in several countries worldwide. The Q-Robot collects samples randomly from multiple points across each load’s length, width and depth, offering a truly representative measure of moisture content that traditional manual sampling cannot match. Real-time moisture data is analyzed and stored securely in a cloud-based database, allowing facility operators to make fast, data-driven decisions for procurement and operational adjustments. This approach not only helps avoid overpayment for biomass but also enhances safety and efficiency in handling deliveries.

Prometec Q-Robot offers both fully automated and semiautomated sampling stations, adaptable to diverse facility needs. Designed to work seamlessly with various crushed and solid materials, Q-Robot delivers precise, representative samples, addressing the limitations of manual sampling methods. Real-time moisture data empowers biomass facilities to reduce procurement costs, enhance safety and optimize fuel handling processes.

How it Works

The Q-Robot truck sampler drills multiple samples randomly at various depths and points across each load, combining them to form a single, representative sample of the entire load’s moisture content. With a built-in machine vision system, Q-Robot identifies optimal sampling spots and avoids structural obstructions, ensuring accurate and safe sampling. Additionally, the system calculates load volume, providing a crucial input for real-time moisture data calculations that support better logistics and supply chain management.

Samples taken by Q-Robot can be analyzed immediately by its integrated real-time moisture sensor or sent to a lab for further testing. Prometec’s multiyear field studies show that Q-Robot significantly improves moisture data accuracy, reducing efficiency calculation errors by an average of 5% compared to manual sampling methods. This increased accuracy supports better overall energy efficiency for power plants.

Precise moisture measurement can make a multimillion-dollar difference for biomass power facilities. By adopting automated, real-time solutions, biomass energy operators will not only save on procurement costs, but also improve operational efficiency and safety.

Author: Andy Korhonen

Vice President, U.S. Operations

Prometec Oy

www.prometec.fi

andy@prometec.fi

LINK to the article published by Biomass Magazine.