Online moisture measurement

Online moisture measurement

We have introduced a new innovation to the market, an integrated moisture measurement device in the Q-Robot sampler, which measures the moisture content of the load even before unloading. This enhanced Q-Robot is referred to as Q-Robot M. The moisture data is so precise that it can be used as a basis for billing, and the measurement result is ready within seconds after sampling. The device measures samples one by one as the Q-Robot collects them from the load.

Q-Robot M combines three different technologies to ensure accuracy in the results: electronic impedance spectroscopy, acoustic emission, and machine learning. In addition to moisture measurement, the integrated acoustic emission sensors in the device can also identify the quality of the wood fuel during sampling. The measurement analyzes the vibration produced by the material as it hits the walls of the collection tube; different materials generate different vibrations. The device is trained and calibrated for the desired identifiable materials.

The first Q-Robot M has been delivered to Fjernvärme Fyn in Odense, Denmark. There, our equipment automatically measures the humidity of around 70 trucks per day.

Online moisture measurement before unloading the cargo

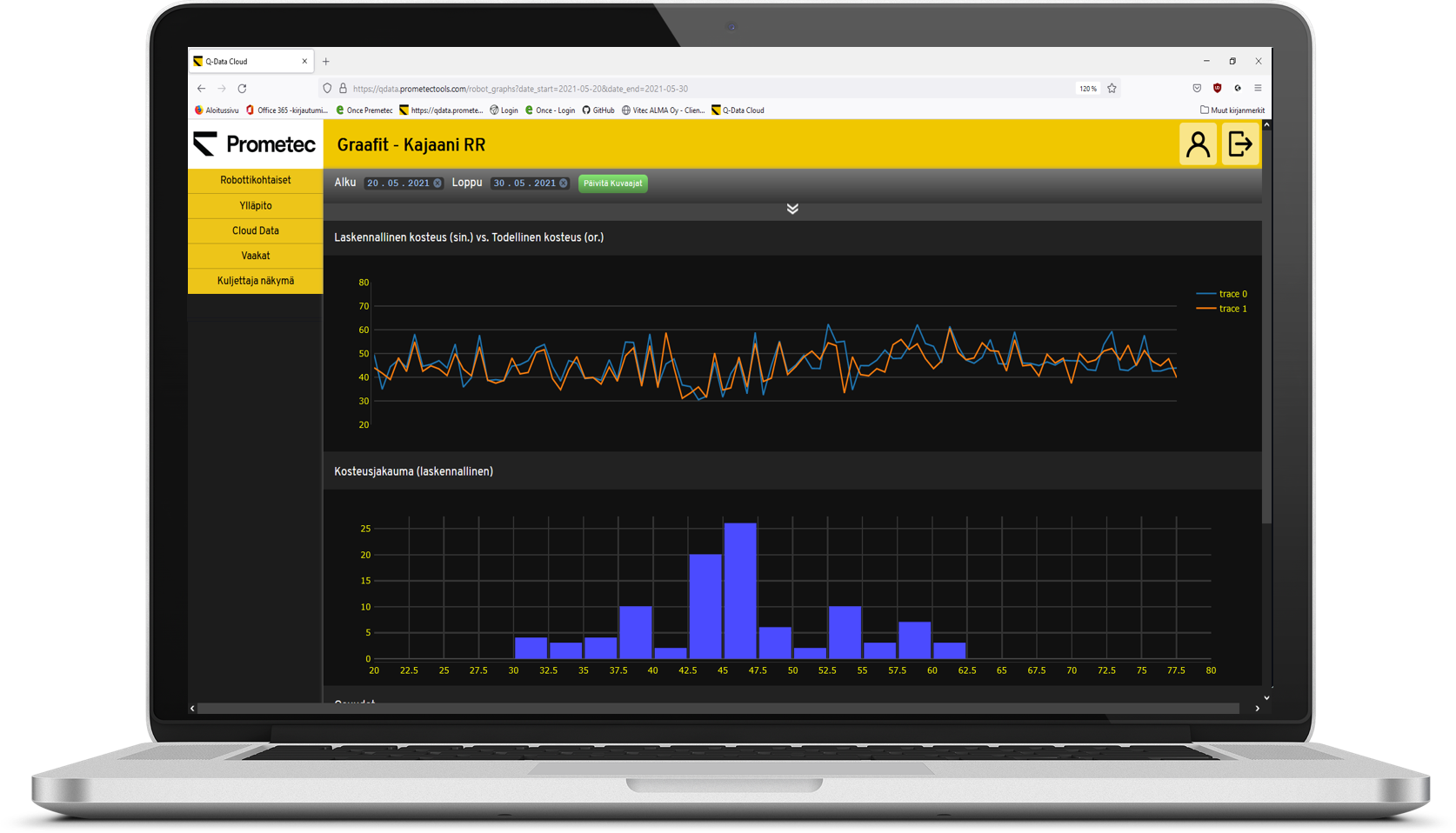

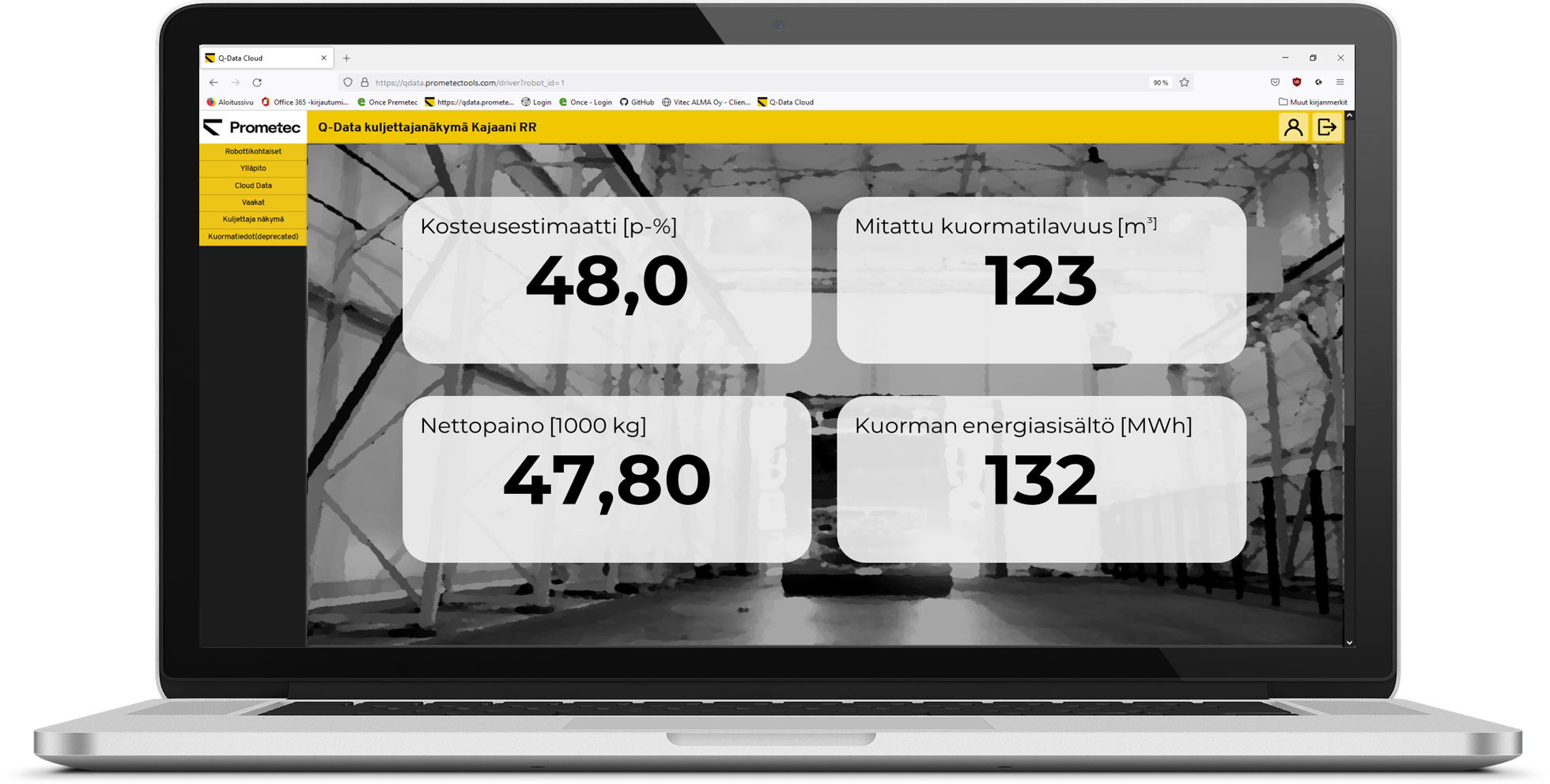

Q-Data enables online fuel reception reporting and includes visual reporting tools for monitoring and controlling fuel quality. With the Q-Data software, moisture data and calculated energy content are made available immediately upon sampling and before unloading the load. In addition to moisture data, other measurements such as volume, obtained through machine vision, can be displayed to the driver as soon as sampling is completed. The software can also provide instructions to the driver based on quality data, such as the unloading point. The software collects data in real-time from Q-Robots and vehicle scales connected to the system and transfers the data to the Q-Data database, which is accessed via a web browser. Furthermore, all data from the Q-Data database can be transferred in real-time to the plant's automation system, allowing the quality data to be utilized in controlling unloading points, storage silos, and ultimately, the combustion process

Q-Data benefits

- All load weight data and data measured by the Q-Robot are available in real-time in the cloud service.

- Online volume data of the load, measured moisture content, and calculated energy content are immediately transmitted upon completion of sampling.

- Informing the driver at the unloading site based on moisture data.

- Generating an alert for the operator if the quality specification of the load is not met.

- Online data can be directly transferred to the plant's automation system, where it can be used for optimizing the combustion process.

- Informative dashboard displays for quality management.